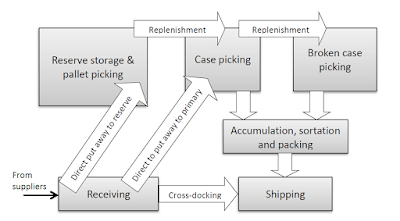

The main warehouse activities include: receiving, transfer, and put away, order picking/selection, sortation/accumulation, cross-docking, and shipping. The image below is the typical warehouse functions and flows.

It is important to understand the relationships between the different processes in order to obtain the most optimal solution and hence minimizing the handling costs. The most important aspects of the warehouse functions are described below.

Receiving

Receiving activities consist of unloading items from the transport carrier. In some cases, the incoming goods pass through the warehouse without being put away in stock. This is referred to as cross-docking, which is an activity where the incoming delivery is sorted directly on outgoing transport carriers.

Put away and transfer

This process involves the transportation of items to designated storage locations. And may also include repacking and physical transport from and to different areas in the warehouse.

Picking

The order picking process is identified as the most labor-intense activity in a warehouse and consequently the most costly. The costs related to order picking can be as much as 55 percent of the total warehouse operational expenses.

The order picking process includes activities; clustering and scheduling customer orders, releasing orders to the ground, picking of things from storage locations, then eliminate them.

Customer orders include order lines and each individual order line represents a unique item or stock-keeping unit (SKU). Order lines can be divided based on the characteristics of the product. The items are often picked in either a full pallet, case (carton) pick, or broken case (unit) pick. Usually all three options exist in a warehouse. Two basic picking variants are often distinguished: pick by article and pick by order. With pick by article, an operator picks multiple customer orders simultaneously whereas, with a pick by order, one customer order is processed at a time. There are many variants and customized solutions in between these two alternatives.

Packing

When the picking process is finished the orders must be packed and sorted on the right unit load (e.g. pallet) before leaving the warehouse

No comments:

Post a Comment