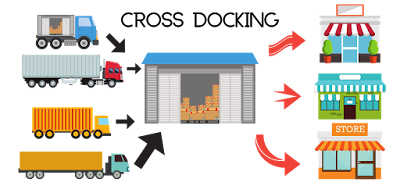

Cross-docking involves delivering products from a producing plant on to customers with little or no material handling in between. Cross-docking not only reduces material handling but it reduces the necessity to store the products within the warehouse. In most cases, the products sent from the manufacturing area to the dock are allocated for outbound deliveries.

Cross-docking solutions allow companies to boost shipments to customers, which suggests that customers often get what they need once they want it the goal of an optimizes supply chain. But cross-docking solutions also go with risks that companies should consider before implementing them into standard operating procedures.

Benefits

Many companies have benefitted from using cross-docking. Some of the benefits include:

Reduction parturient costs, because the products not require picking and putting away within the warehouse

Reduction within the time from production to the customer, which helps improve customer satisfaction

Reduction within the need for warehouse space, as there's no requirement to store the products

Types of Cross-Docking

There are a variety of cross-docking scenarios that are available to warehouse management. Companies will use the sort of cross-docking that's applicable to the sort of products that they're shipping.

Cross-Docking in Manufacturing: This procedure involves the receiving of purchased and inbound products that are required by manufacturing. The warehouse may receive the products and prepare sub-assemblies for the rally orders.

Distributor Cross-Docking: This process merges inbound products from different vendors into a mixed product pallet, which is delivered to the customer when the final item is received.

Transportation Cross-Docking: This operation combines shipments from a variety of various carriers within the less than truckload and small-package industries to realize economies of scale.

Retail Cross-Docking: This process involves the receipt of products from multiple vendors and sorting them onto outbound trucks for a variety of retail stores. They would procure two sorts of products, items they sell every day of the year, called staple stock, and enormous quantities of products that are purchased once and not usually stocked again.

Opportunistic Cross-Docking: this will be utilized in any warehouse. It involves transferring a product directly from the receiving dock to the outbound shipping dock to satisfy a customer sales order.

Products Suitable for Cross-Docking

There are materials that are better suited for cross-docking. The list below shows below:

Perishable items that require immediate shipment

High-quality items that don't require quality inspections during goods receipt

Products that are pre-tagged (barcodes, RFID), pre-ticketed, and prepared purchasable

Promotional items and items that are being launched

retail products with a constant demand or low demand variances

Pre-picked, pre-packaged customer orders from another production plant or warehouse

Risks Associated with Cross-Docking

Because products aren't put away within the company's prescribed fashion during cross-docking, there's an increased risk associated with loss of internal control by using the tactic the future.

To deployment cost-docking effectively, warehouse and provide chain managers should put into place potent internal control processes and train warehouse employees on those processes. Even though cross-docked items aren't put away within the company's prescribed fashion, that doesn't recoup the necessity to account for those goods while accounting for stock and reconcile supplier and customer invoices.

No comments:

Post a Comment